Why is PVC halls considered the market leader?

In the evolving landscape of temporary and semi-permanent buildings, PVC halls stand out as a leader in innovation, durability and cost-efficiency. They have taken a market-leading position, becoming as dominant today as arched and veneered halls were decades ago.

These polyvinyl chloride (PVC) fabric structures offer a range of advantages that put them at the forefront of lightweight construction. In this post, we'll dive into the unique value proposition of PVC corrugated by exploring their advantages in terms of versatility, durability, cost-effectiveness and environmental impact, and trying to answer all your questions - even the ones you don't know how to ask right away.

Unique versatility

PVC greys are valued for their unrivalled versatility, providing solutions for a wide spectrum of applications from weddings and corporate events to storage and industrial uses. Unlike traditional buildings, PVC halls can be erected on a wide range of surfaces, concrete, stone or asphalt without the need for a separate foundation, making them the ideal solution for a wide variety of businesses requiring additional workspace.

Their modular design allows for easy customisation, allowing users to choose the area and volume of the building to suit their specific needs, whether it's a small car garage or a large-scale warehouse. In addition, the shed can be either open-plan or with different door options. Here, for example, is more on PVC curtains.

Good durability

When it comes to durability, PVC tents are in a class of their own. Our portfolio includes a reinforced cover from German manufacturer Mehler Texnologies - this PVC fabric is designed to withstand harsh weather conditions, including heavy rain, strong winds and even snow. A hot-dip galvanised metal frame adds strength to the building, with a highly controlled manufacturing process and inspection (QA and QC).

This resilience ensures that Wiola's halls provide reliable shelter and protection for people and goods, whatever the external environment. In addition, the material's UV resistance helps to maintain the aesthetic appearance and structural integrity of the tent over time, making it a long-term investment.

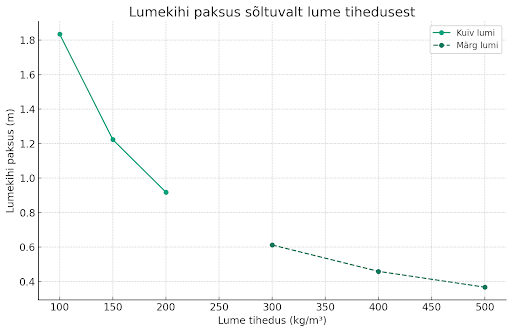

The load bearing capacity of Wiola halls is 1.8 kN/m2. Let's look at the most likely roof loader in Estonia - snow. The graph shows the approximate allowable snow layer thickness depending on the snow density - for dry or wet snow.

In the case of dry snow, with a density varying from about 100 kg/m³ to 200 kg/m³, we see that the thickness of the snow layer can vary from about 1.83 metres (at 100 kg/m³) to 0.92 metres (at 200 kg/m³).

In the case of wet snow with a higher density (300 kg/m³ to 500 kg/m³), the allowable thickness of the snow layer is significantly lower, ranging from about 0.61 m (at 300 kg/m³) to 0.37 m (at 500 kg/m³).

This shows how the snow characteristics have a significant influence on the thickness of the snow layer that can be allowed on the roof and why it is important to pay attention to this aspect of maintenance in winter.

Cost efficiency

One of the most convincing arguments for PVC tents as part of an irresistible value proposition is their cost-effectiveness. Compared to the construction of a permanent building, a PVC tent requires a significantly lower initial investment. This affordability does not compromise quality or functionality, as these tents offer powerful performance and versatility.

In addition, their ease of installation and dismantling means reduced labour costs and the flexibility to relocate the structure if necessary, further increasing their economic attractiveness. Cost-efficiencies apply to both the one-off investment in erecting the hangar and the low maintenance requirements over its lifetime - all alternatives require more costly maintenance plans.

Maintenance needs - what maintenance needs?

The maintenance needs of halls are generally low. PVC fabric is weatherproof and UV-resistant, which means it can withstand the damaging effects of the sun and does not fade easily. The PVC material is also resistant to mould and rot, which is particularly important in humid climates.

Regular cleaning to remove dirt and debris is usually enough to keep PVC grey in good condition. In addition, should the PVC fabric become damaged, repair is relatively simple and cost-effective, allowing new sections to be cut and installed without major expense.

So what to maintain in the first place - once a year you could do a visual check on the condition of the structures, to make sure, that the cover is tight, the bolted joints are tight and, of course. - there should be no mechanical damage and no excessive snow load as mentioned above.

But if you've discovered any of the above, or something unexpected, contact us for maintenance.

Minimum environmental impact

In today's world of construction projects, environmental impact considerations can no longer be overlooked, nor should they be. In this respect, PVC tents are highly valued, offering a sustainable alternative to traditional construction methods. The light weight of PVC fabric (900 g/m2) reduces transport emissions and the recyclability of tents minimises waste.

In addition, the energy efficiency of PVC tents, especially when equipped with insulation features, can lead to lower heating and cooling costs, contributing to a smaller carbon footprint. Most importantly, the material and resource footprint of the building as a whole is much lower than alternatives.

Installation is quick and easy

The speed and ease of installation of PVC tents is unmatched by conventional construction. These structures can be erected in a fraction of the time it takes to construct a permanent building, ensuring rapid deployment for urgent requirements. This feature is of particular benefit to companies and organisations that need to respond quickly to market demand or unexpected events, giving them the ability to take advantage of opportunities immediately.

Let's give you an example of our four options. See more options here!

- 5m x 10m x 3m high building - surface area 50 m2 and volume 150 m3 - installation time approx. 2-4 days;

- 15m x 40m x 4m high building - area 600m2 and volume 2400 m3 - installation time about a week and maybe a few days;

- Greater PVC grey - up to 1000m2 - installation takes about 10 days;

- Very large greys - over 1000 m2 - installation in about 2 weeks.

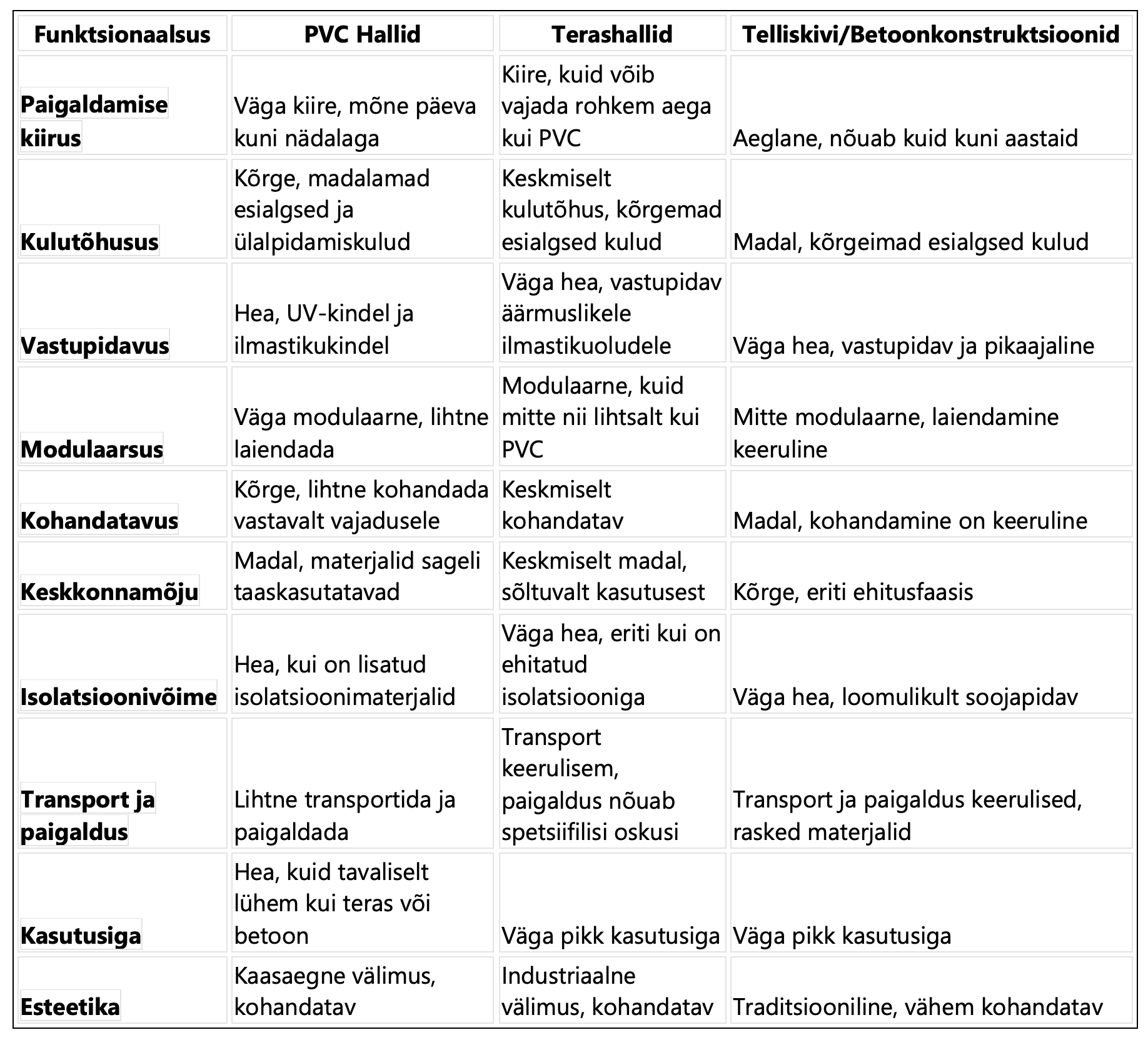

Comparison with alternatives

PVC coating can be made aesthetically attractive and visually distinctive

The PVC foyer is highly visually adaptable to the client's brand, allowing a high degree of customisation in design and functionality. From choosing colours and patterns that reflect the brand identity to adding window, door and floor options that enhance the user experience, the possibilities are almost limitless.

This adaptability not only ensures that the tent meets the specific needs of the users, but also contributes to the aesthetics of the structure and the way it fits into its new environment, making it an attractive choice wherever you have a new facility planned.

To sum up

A PVC hall is the best solution for your lightweight building needs - there is no other conclusion.

Such tents represent the modern lightweight construction industry, offering an unrivalled value proposition that is hard to ignore. Their versatility, durability, cost-effectiveness, minimal environmental impact, ease of installation and aesthetic appeal make them the ideal choice for a wide spectrum of applications. Whether for temporary events, semi-permanent installations or industrial uses, PVC marquees offer unparalleled performance and value, cementing their status as the number 1 choice for lightweight structures.

In a society where our expectations and demands are higher than ever and we continue to seek ever more efficient, sustainable and cost-effective building solutions, PVC roofs stand out for their exceptional value proposition, ready to meet the diverse needs of the modern world.